ISO 13485 Medical Cable Manufacturer Custom Round&Parallel &Flat&Coild Cable with ISO10993 Biocompatible TPU TPE Materials for ECG SpO2 and Medical Equipment

Basic Info

| Model NO. | Medical-Cable-13485 |

| Feature | Reusable |

| Certification | ISO13485 |

| Conductor | Tinned Copper |

| Jacket | TPU |

| Shield | Tinned Copper |

| Fast Prototype | 2-5 Days |

| Transport Package | Standard Export Carton or Customized |

| Specification | 60*42*0.035 |

| Trademark | YQF |

| Origin | China |

| HS Code | 8544422100 |

| Production Capacity | 80000km |

Product Description

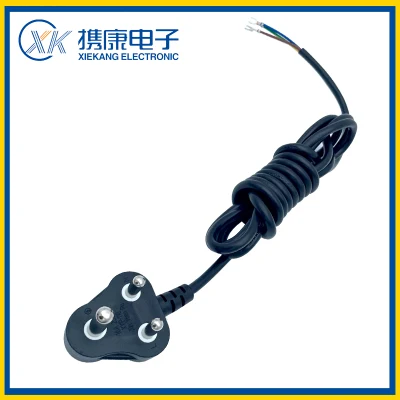

ISO 13485 Medical Cable Manufacturer Custom Round&Parallel &Flat&Coild Cable with ISO10993 Biocompatible TPU TPE Materials for ECG SPO2 and medical equipment(Free Design)Medical devices and equipment are critical to life and safety ,Medical cable manufacturing as a key part of medical interconnect solutions, plays an critical roles in health care and life saving.

As an medical cable expert, we design and manufacture a wide range of cables and wire for the medical equipement factory and medical accessories manufacturer(we are not end-user oriented) . From designing, prototyping for testing to mass-production of final custom cable,we make within 7-10 working days with only charging material cost(free design,free consult,free existing samples available)

The Application Environment For Medical Cables

Medical cables are usually potential to touch skin and need to sterillize .during the design and manufacturing,following issues is worthy of our attention:

• Disposable/Reusable cable designs• Low noise shielding

• Resistance to steam, gamma, ETO and other sterilization methods

• High temperature insulators

• Hi-Flex and long-life cable designs

• Potting and pressure testing

• Chemical Resistance

• Serialization and lot control

• Statistical process control

• Medical-grade materials - including TPE, polyurethane and silicone

• EMI suppressionThe Medical cable we made can devided into many groups based on their shape,or application or materialsSuch as

Coiled Cable for Defibrillator as following:

Single lead to 18 leads cable for ECG Monitoring System as following:

Coaxial Low Triboelectrical Noise Cable for micro signal devices,including ECG monitor

1P+2C/3C/4C/5C/6C/7C for Spo2 Extension Cable

| Conductor Options | Shielding Options | Enhancement Options | Insulation & Jacketing Materials | |

| Bare Copper | Bare Copper Braid | Strength Members | CPE/Chlorinated Polyethylene | PFA/Perfluoroalkoxy |

| Tinned Copper | Tinned Copper Braid | Water Blocking | EPDM/Ethylene Propylene Diene Monomer | PFE/Perfluoroelastomer |

| Silver Plated Copper | Silver Plated Copper Braid | Fillers | ETFE/Ethylene Tetrafluroroethylene | PP/Polypropylene |

| Nickel Plated Copper | Nickel Plated Copper Braid | Rods | FEP/Fluorinated Ethylene | PTFE/Polytetrafluoroethylene |

| High Strength Alloys | High Strength Alloys Braid | Tubes | Foamed FEP | PUR/Polyurethane |

| Copper Clad Steel | Copper Clad Steel Braid | Foamed PFA | PVC/Polyvinyl Chloride | |

| Prebonded Conductor | Stainless Steel Braid | Foamed PE | Silicone | |

| Overcoated Conductor | Aluminum Mylar Foil Shield | Foamed TPE | Tefzel | |

| Topcoated Conductor | Spiral Shield | Halar | TFE/Tetrafluoroethylene | |

| HDPE & LDPE | TPE/Thermoplastic Elastomer | |||

| Hytrel | TPR/Thermoplastic Rubber | |||

| mPPE/Modified Polyphenylene | XLPE/Cross-Linked Polyethylene | |||

| Neoprene | XLPO/Cross-Linked Polyolefin | |||

| PE/Polyethylene | ||||

Custom Medical Cable Manufacturer -3 Key Factors To Make Your ChoiceTo choose a reliable custom medical cable manufacturer is critical to a medical device manufacturer. When you are making a choice, there are 3 factors you have to consider:

First,Are They An Experienced Medical Cable Manufacturer?

Working with a experienced medical cable expert is critical if you want to keep your medical devices running safely, functionally and durable. A medical cable manufacturer must be ISO 13485 certified. This is the most direct way you can make a rough judgment how many years they have engaged in medicalcable. But this is not totally reliable, some cable manufacturers would like to apply all types of certifications when then founded the company.An experienced medical cable factoryusually will ask you following questions when you make an inquiry if you did not give them your exact requirement:- What medical device will the medical cable be applied to/used for?

- What is the acceptable OD(out diameter)and tolerance of the cable

- What is the gauge of each wire? Or how many strands of specific conductor you would like each wire to be

- Where is the medical device being used (i.e. X-ray room, doctor's office, Ambulance, operating room, etc.)?

- Do you prefer disposable medical cable or reusable cable?

- What are your sterilization methods (chemicals or physical? What are the chemical sterilization materials? What is thetemperature, pressure, Ray (Ultraviolet, note: X-ray not used for sterilization)?

- Will the medical cable be exposed to any other chemicals or fluids? Will there be any extra coat to protect the cable?

- What is the contacting level between the cable and patient (i.e. absolutely no contact, occasional contact, alwayscontact, implanted, etc. This relates to biocompatibility and material choosing)?

- Do you have any supplementary requirements (such as, UL94 Level/framing rate, temperature resistant,ultra-flexible, Matt or Glossy, coiling etc.)?

Second:what Are Their Producing Equipment And Laboratory Testing Devices?

Medical cable manufacturing has much more processing procedures than normal cable. And in most situation, it demands the conductors to be as thin as possible. For thesame gauge cable, thinner conductor will make it more flexible and better electronic performance. Not all conductor stranding machine can strand thin conductors as they are easy to break.so the precision level can determine the quality of the wire in some way besides of staff expertise. For testing devices, without the right testing devices, you cannot make related testing, such as RoHS,High Frequency,Triboelectric noise ,Tensile…(please refer to our Lab)Third:Strategic Partners

For most industries, Partners belongs to commercial secret. For medical cable field, medical devices manufactures has a AVL(approved vendor list),similar to UL in some way. If a medical cable manufacturer is in the AVL of many worldwide famous brands,this is the easiest way for you to choose it as your potential partner too. YQFhas be a partner for many famous brands and in their AVL for many years,contact us for trading reference if you are making medical cable supplier.Performance Requirement:

1,High pressure resistance: AC 1500V, leakage current 0.25Ma/Min DC5000V,the leakage current less than 0.25mA,no breakdown

2,Insulation resistance:DC500V,(1M) the resistance are more than 10000M

3, Bending test: loading 800g,±90°40times/min more than 5000time

4,Conductor resistance: < 0.239Ω/M

Our Advantage:

1, We are manufacturer of more than 16years' experience, produce all the products displayed in our website.Providing OEM/ODM service

2,Free samples available with 3days delivery

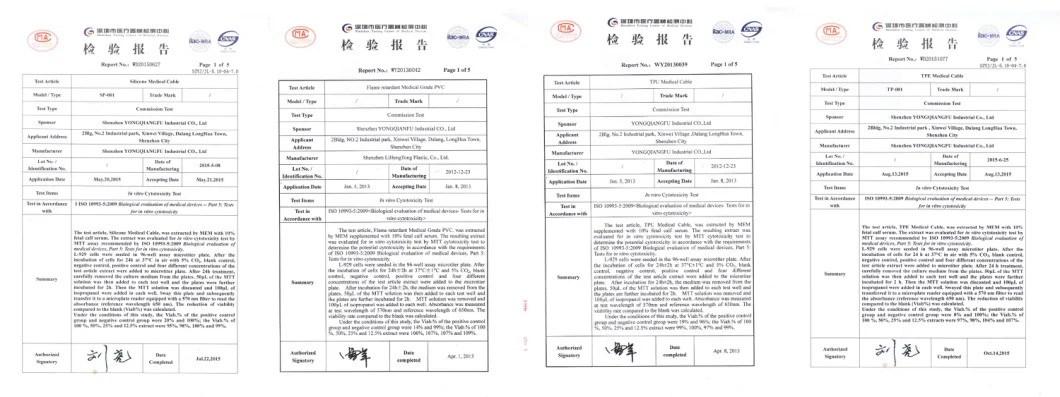

3,Certifications: ISO9001:2008,ISO13485-2003 ISO14001-2004

4Warranty: 12months for reusable SPO2 sensor cable,6months for ECG cables

5,Top-quality,non-toxic, anti-interference,soft and durable TPU cable

6, Excellent skilled staffs with professional product knowledge and high work efficiency to solve your any problems within 6hours.

7,strictly testing before packing and shipping:

1) 1.Bending testing

2).Resistance testing

3).Capacitance testing

4).Dielectric strength testing

5).Aging testing

6).Low noise testing

A leading manufacturer of customized wires and cables

1,Focus on Cable R&D and Manufacturing for 16 years

2,Annual output: 80,000KM ,round the Earth for 2 circle

3, ISO 9001,ISO13485,ISO14001 certified

4,Repeated order rate:100%

5,30% of our partners have been working with us for 10 years

Products Certificates We have