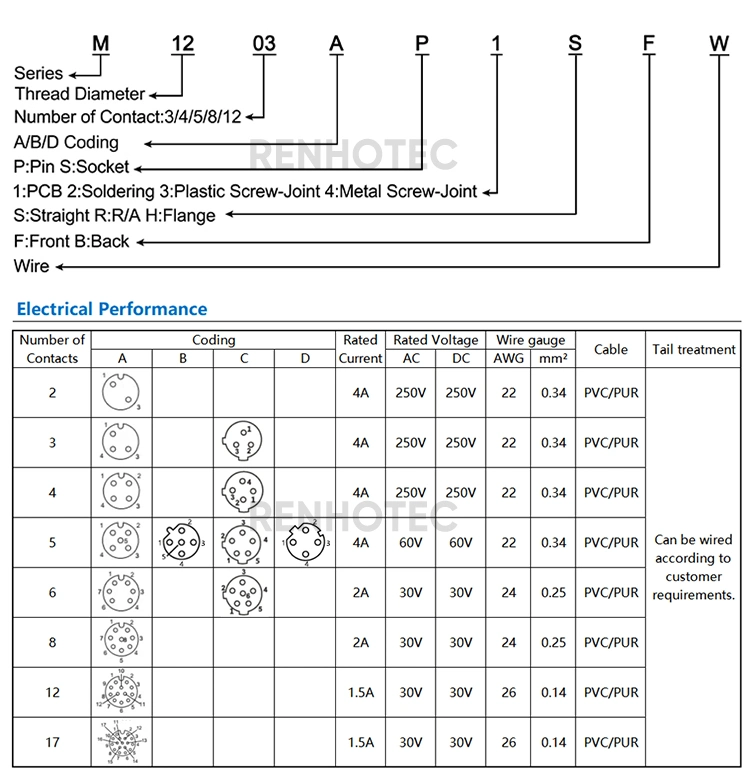

Circular Series Assembly Copper Contact M12 5 Pin Male Connector

Basic Info

| Model NO. | M12 5 Pin Male Connector |

| Contact Material | Brass |

| Surface Treatment | Nickel Plating |

| Housing | Copper Alloy |

| Connector Type | M12 Sensor Connector |

| Standard | IEC 61076-2-101 |

| Coupling | Threaded Connection |

| Orientation | Straight |

| Contact Count | 3 4 5 8 12 Pin |

| Body | Brass |

| Plating | Nickel |

| Contact | Brass, Gold Plating |

| Coding | a / B / D / T / X |

| Rated Voltage | 250V for 3 4 Pin 60V for 5pin 30V for 8 12 17pin |

| Rated Current | 4A for 3/4/5/6 Pin, 2A for 8pin, 1.5A for 12/17pin |

| Shell Material | Plastic / Metal |

| Thread Aperture | Pg9 : 6~8mm / Pg7 : 4~6mm |

| Termination Style | Screw-Joint / Solder Type |

| Shield | Shield / Unshielded |

| Transport Package | Standard Package |

| Specification | M12 Sensor Connector |

| Trademark | Renhotec |

| Origin | Guangdong |

| HS Code | 8538900000 |

| Production Capacity | 100000PCS/Week |

Product Description

Detailed Photos

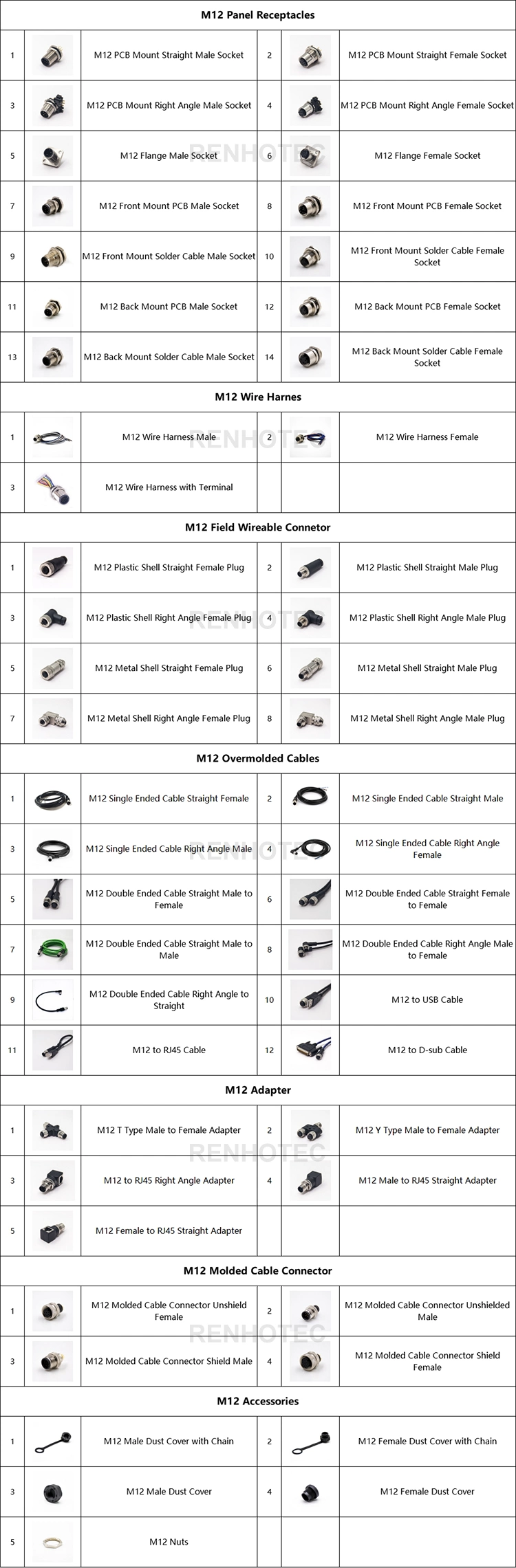

Full Series M12 Field Wireable Connetor

All types of Circular Connector from OEM Manufacturer in China

The M12 field wireable connectors are used to build custom patch cables, provide a quick-disconnect for a device, terminate field devices on an I/O block, or bring multiple sensor signals into one port. M12 field-installable connectors support higher bandwidth while providing an IP67 rated solution for demanding applications.

Products Feature

M12*1 thread locking mechanism, anti-vibration locking design;

Easy quick connect and disconnect coupling;

Pin configurations: 2, 3, 4, 5, 8,12 and 17 positions;

A, B, C, D, K, L, X, S, T coding available;

Meets IP67/IP68 waterproof requirements;

Temperature Range: -25°C ~ + 85°C ;

Alternative mount arrangements for solder cup or PCB;

Panel Mount and distribution version available;

Benefits

Nickel plated brass

High durability, corrosion resistance, oxidation resistance

Strong waterproof performance

Available as a loose piece or as a pre-made M12 cables

Exquisite Craftsmanship Makes Connections More Secure

Thickened pins/long life Copper-zinc material, high resistance, wear resistance Threaded cable, easy to remove and plug, tightly combined, and not easy to fall off.

Safe and Reliable Meet the Standards to Create Safety

Pure copper gold-plated contacts with excellent electrical conductivity Fixed key position, multi-key position to prevent blindness, MIS insertion, skew insertion Strong waterproof performance, in line with IP67/IP68 waterproof requirements.

Stable Performance, Strong and DurableHigh-quality PA66 housing Thread locking mechanism, shock-proof locking design Thickened nylon is corrosion-resistant, non-flammable, and has good insulation properties.

Basic Attributes

| Connection Type | M12 Field Wireable Connector |

|---|---|

| Gender | Male / Female |

| Orientation | Straight / Right Angle |

| Shell Material | Plastic / Metal |

| Termination | Screw Joint / Solder Type |

| Cable OD | PG7(4~6mm), PG9(6~8mm) |

| Shield | Shield, Unshielded |

| Pin Contact | CuZn |

| Socket Contact | CuSn |

| Contact Plating | Au |

Performance

| Rated Voltage | 250V for 3/4 Pin, 30V for 8/12/17 Pin, 60V for 5 Pin |

|---|---|

| Rated Current | 1.5A for 12/17 Pin, 2A for 8 Pin, 4A for 3/4/5 Pin |

| Insulation Resistance | ≥100 MΩ |

| Contact Resistance | ≤5 MΩ |

| Coupling | Threaded Coupling |

| Mechanical Operation | >500 Mating Cycles |

| Wire Gauge | 0.14/0.25/0.34/0.5mm²/(26/24/22/20AWG) |

| Temperature Range | -25°C ~ + 85°C |

| Protection Degree | IP67 / IP68 |

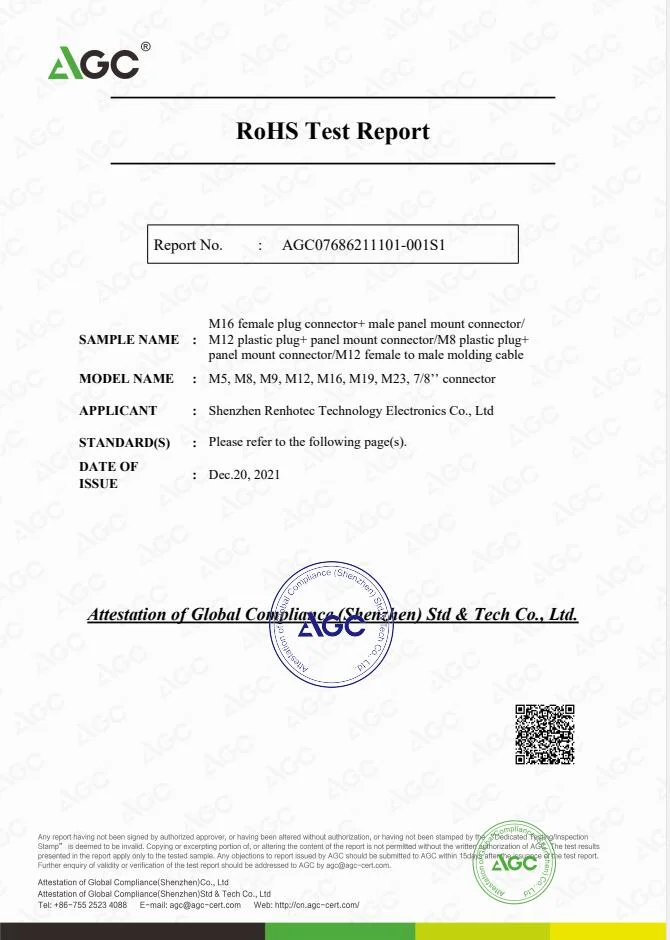

Certifications

Company Profile

Renhotec Hardware Electronics

RENHOTEC is a full-service leading global supplier of a wide variety of standard and custom RF coaxial connectors, cable assemblies and unique solutions for today's cutting edge applications.

RENHOTEC is fully committed to meeting the needs of our customers, we offer a wide range of RF connector interface types and are able to produce custom products for specific applications.

Our team is always focused on designing, developing and taking pride in custom innovative solutions to meet our customers' needs.

- Acquired ISO9001, ISO14001, QC080000 and TS16949 certification.

- All items are in line with EU ROHS and REACH environmental requirements.

- Markets supported include automotive, medical, instrumentation, telecom and wireless etc.

Our Advantages

Customized Design

Professional engineer team help you with drawing design and provide you suggestions based on your special electrical and environmental performance requirements.

Technology Improvement

Establish and optimize the process of the production line. Continuous improvement to make sure the targeted quality and yield achieved and maintain

Quality Inspection Center

With professional inspection center to test the electrical, mechanical and environmental performance and ensure the high quality.

FAQ

1.What is the difference between M12 connector coding?

A-coded mostly used in sensors, actuators, motors, and most other standard devices. it usually between 2 and 12 pins.

B-coded mostly used in network cables for Fieldbus connections, includes systems that operate with Profibus. it typically havebetween 3 and 5 pins.

C-coded primarily used with AC sensors and actuators, and also have a dual keyway for added security. it have between 3 and 6pins.

D-coded typically used in network cables for Ethernet and ProfiNet systems. it transfer data up to 100 Mb and typically provides 3to 5 pins.

S-coded are for ac power application.

T-coded are for dc power application.

X-coded can transfer large amounts of data up to 10Gb at high speeds, it will always have 8 pins.

2. What is the application prospect of M12 connector

M12 connectors will be more suitable for the Industrial Internet of Things (IIoT).

The IIoT is a real-time data connection, driven by processing and transmitting data at faster speeds, on progressively smarter andsmaller machines. The value of the IIoT goes beyond data collection and transmission, it benefits including but not limited to theability to identify disruptions, discovering unused capacity, reducing maintenance costs and downtime, improving safety, andmaximizing overall equipment effectiveness.

M12 connectors' advantages in the speed, reliability, and ruggedness, etc perfect match the smart factories' demand.

3. How to purchase M12 connectors from Renhotec?

1. Please send us the specification or drawing for the items with quantity and performance requirements.

2. We will offer you a detailed quote with lead time, package, payment term for confirm, normally in 3 days.

Packing Details :

1. Our standard packing: Individual part with transparent PE bag with label;

2. OEM package available

Shipping Methods :

1. Samples and Small quantity order will be shipped by FedEx/DHL/UPS/TNT/SF ,Door to Door.

2. Batch goods : Express, By Air, by Sea or by Rail

3. FCL: Airport/Seaport/Railway Station receiving

Lead Time: 1-7 working days for samples; 7-15 working days for mass order.